Enable supplier-built PCF. Collaborate to cut carbon costs.

Introducing the PCF Module. Enable your suppliers to build and share PCFs while cutting carbon. More reliable reporting. Informed procurement decisions. Lower-carbon products.

Ditch top-down for decarbonization

Too often, PCFs are treated as periodic reporting tools. Relying on industry averages, secondary data, and top-down visibility exercises that fall short of driving real change. To cut carbon in products, PCFs must inform decarbonization management not just reporting.

Bottom-up. Supplier-owned.

We put suppliers at the heart of decarbonization, helping them build product-specific PCFs with primary data and take action to cut carbon.

Engage more of your suppliers to build and share PCFs

More reliable reporting

Facility-level PCFs reflect the true carbon impact of how and where products are made.

Informed procurement decisions

Supplier-built PCFs provide visibility of product carbon intensity to inform material sourcing and more.

Lower-carbon products

Supplier-built PCFs create the opportunity for customers to collaborate with suppliers to cut carbon.

The tools suppliers need to build PCFs in one place

Enable suppliers, large and small, to build and share PCFs while cutting carbon.

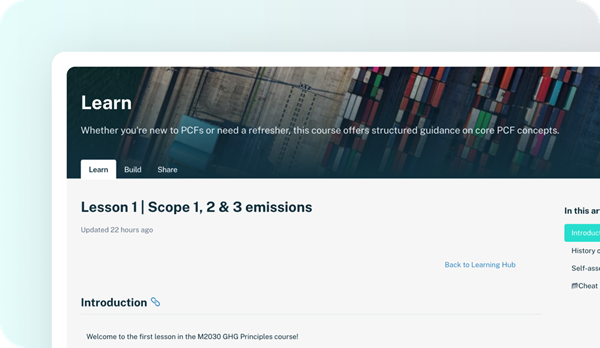

Accessible carbon learning

PCF Academy helps non-experts level up with the knowledge to begin building PCFs.

Streamlined data import

Suppliers gain a head start by importing product and material details.

Guided PCF creation

PCF Builder guides suppliers through each step with automated calculations and access to leading emission factor databases.

Centralized PCF responses

Suppliers can manage and respond to multiple customer PCF requests all from one place.

Simple PCF upload

Suppliers can easily import existing PCFs and share them with customers in platform.

Actionable reduction plans

Suppliers can select and manage actions to reduce carbon from facilities and products.

Hear how Haleon are embedding carbon into sourcing decisions

Chris Low, Head of Sustainability Procurement & Packaging at Haleon, shares how Haleon is embedding carbon into their procurement strategy and the role of the M2030 PCF Module.